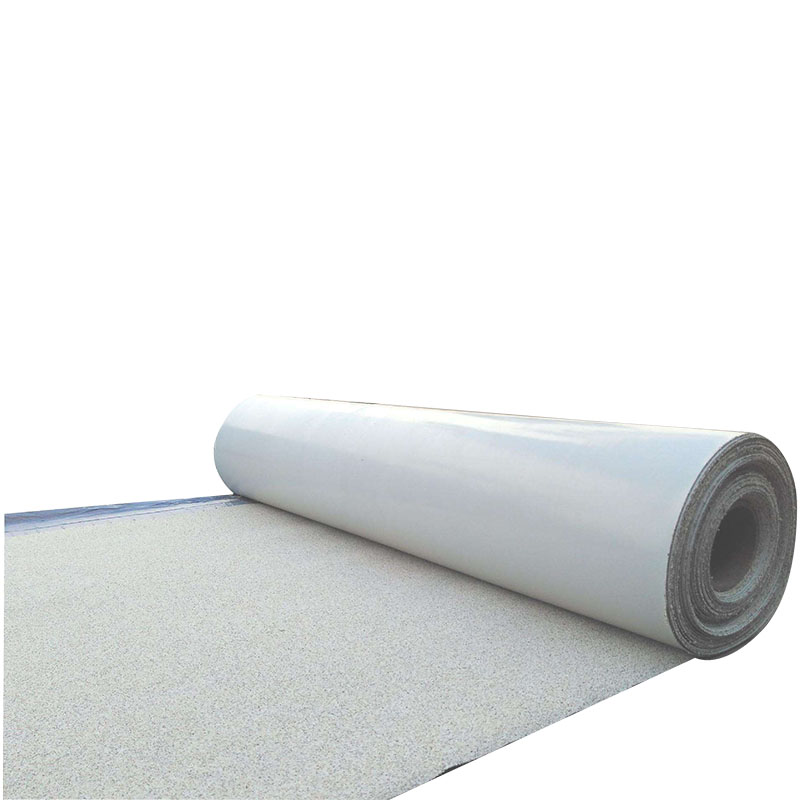

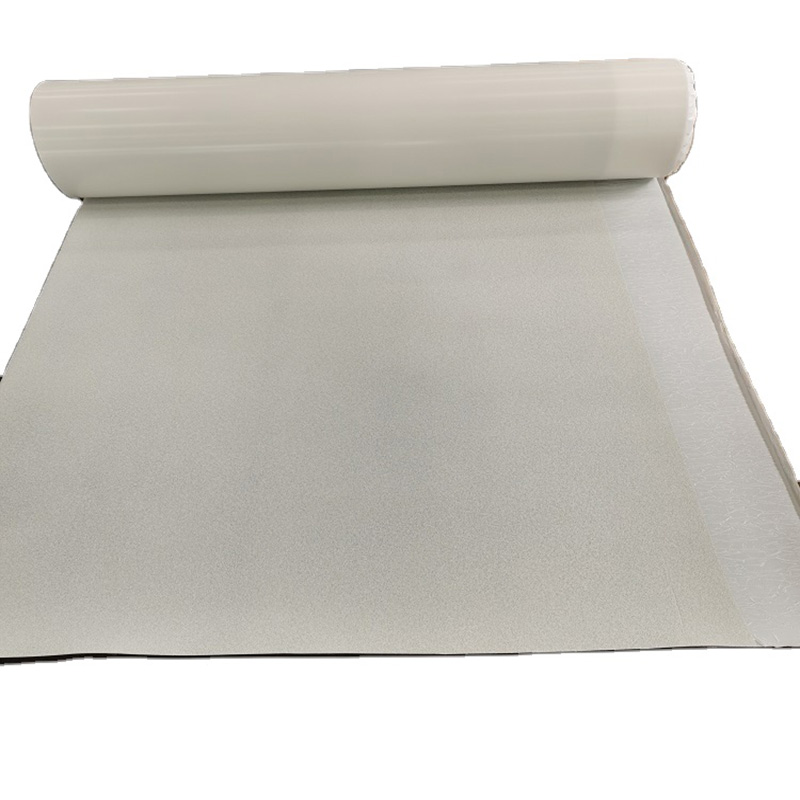

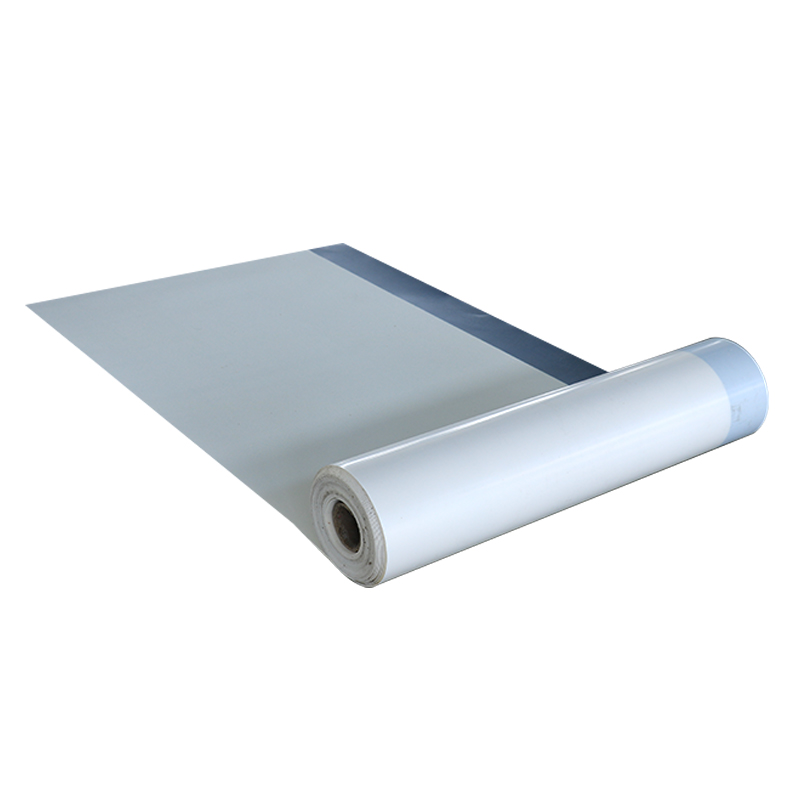

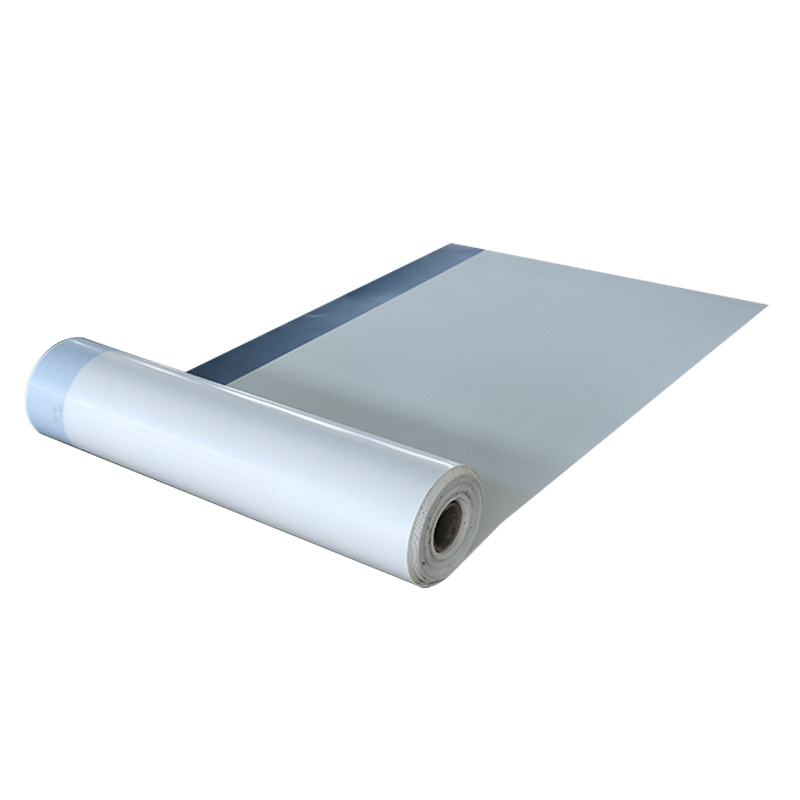

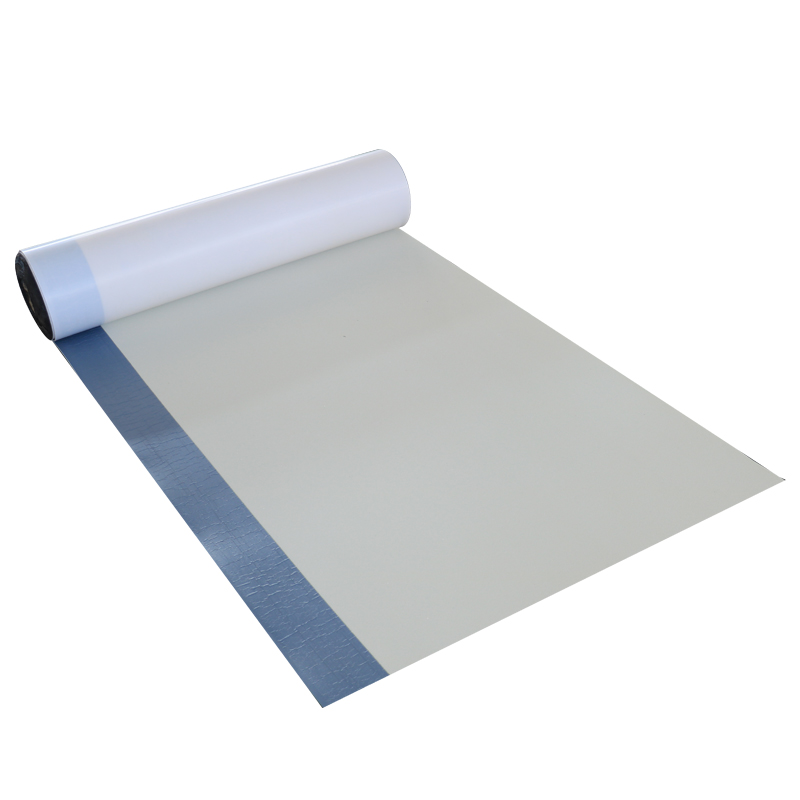

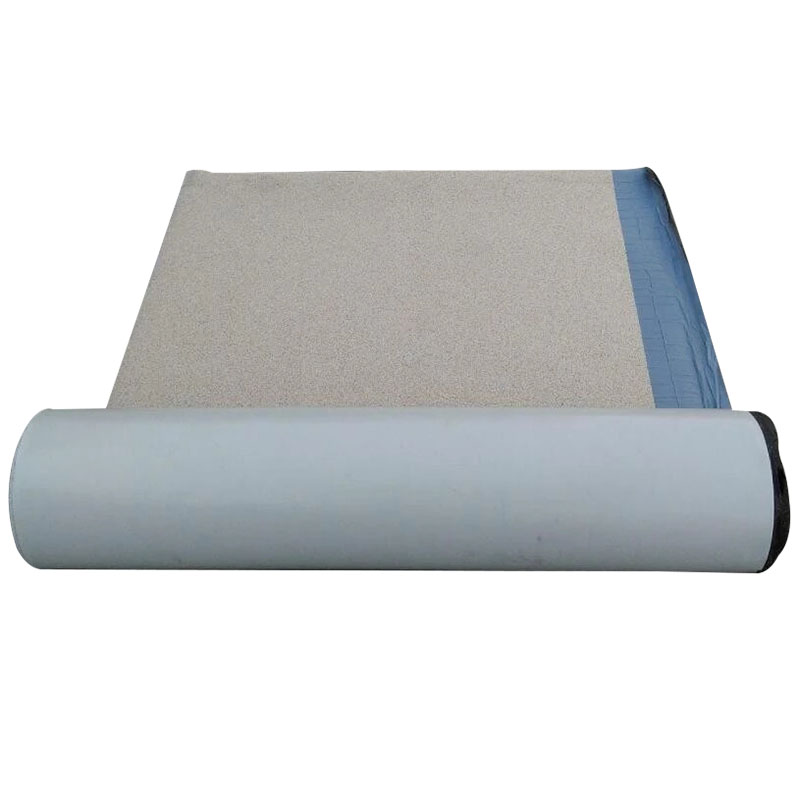

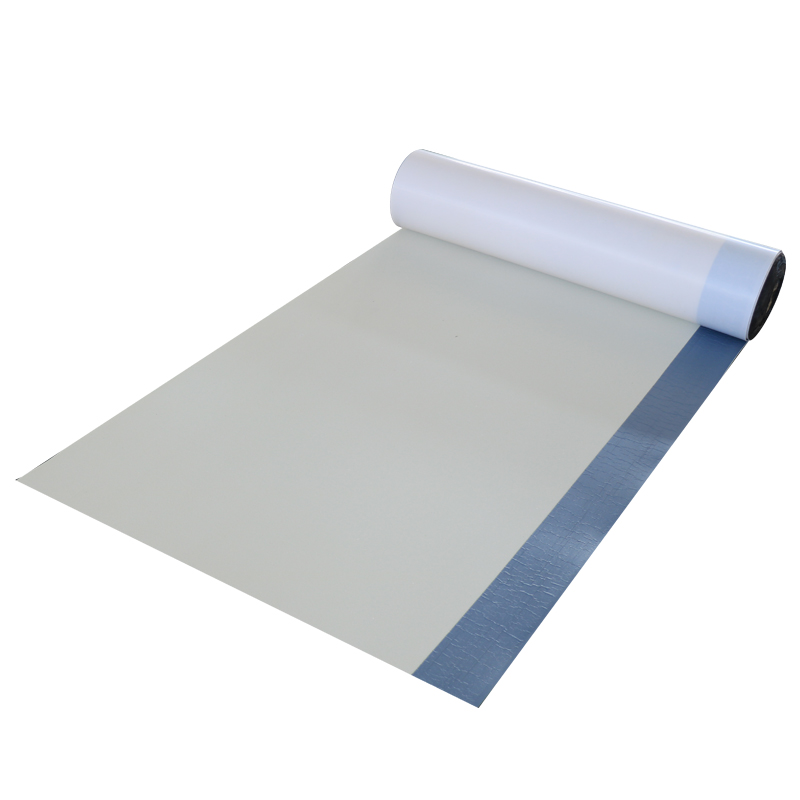

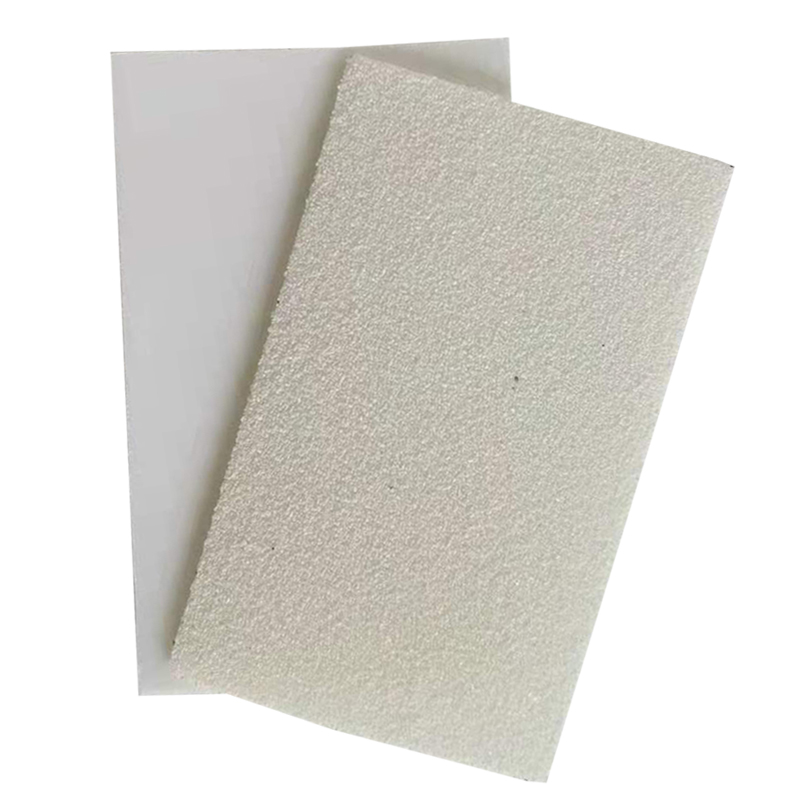

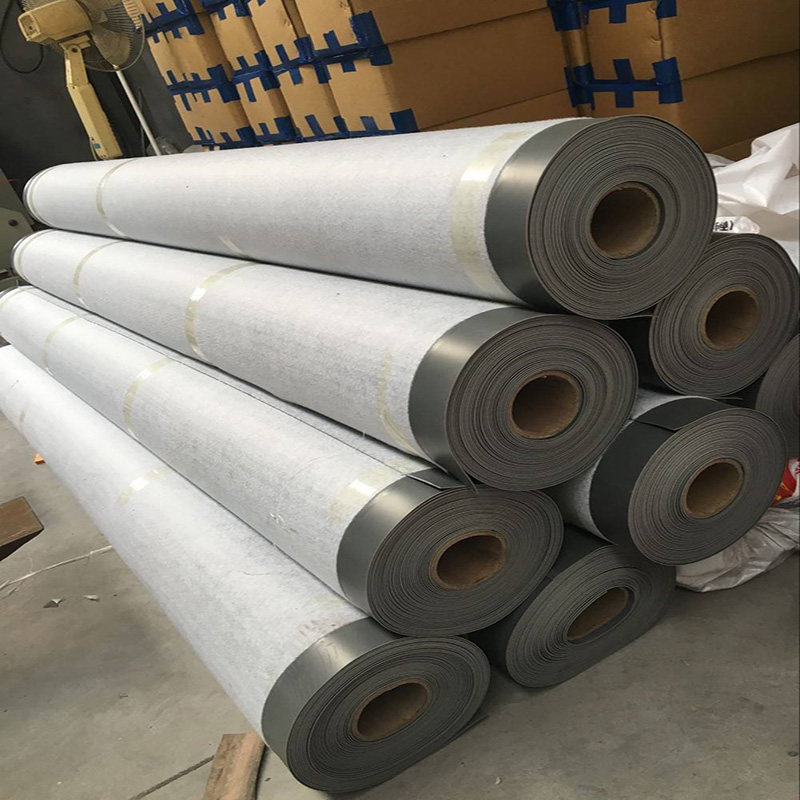

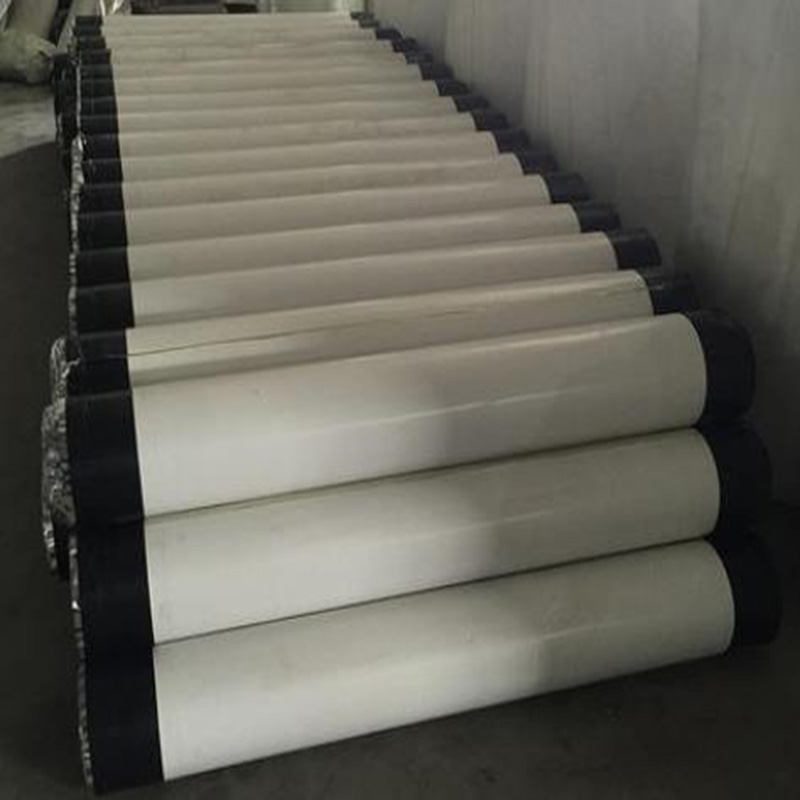

It is made of high density polyethylene (HDPE) sheet, polymer strong reaction self-adhesive membrane and special isolation membrane protective layer. It is a kind of multi-layer composite waterproof material with superior performance specially developed for the parts of underground projects that need to be constructed by pre paving method. The material has good tensile strength and tear strength. It is a new type of waterproof material with excellent performance in underground engineering.

Under the action of pressure, the polymer self-adhesive film and the cement slurry without initial setting in the concrete will creep through the anti adhesion layer to form an effective interpenetrating bond and a huge intermolecular force. After the concrete is solidified, the gap between the polymer self-adhesive membrane waterproof membrane and the main structure is permanently sealed to the maximum extent, and the water channeling channel is completely eliminated.

| No. | Item | Standard Value |

| 1 | Tension /(N/50mm) ≥ | 600 |

| 2 | Elongation (%) ≥ | 400 |

| 3 | Tear strength of nail rod (N ) ≥ | 400 |

| 4 | Resistance to water channeling (hydraulic gradient) | No water channeling at 0.8MPa/35mm for 4h |

| 5 | Low-temperature flexibility | No crack in adhesive layer - 25℃ |

| 6 | Peel strength with concrete with no treatment /(N/mm)≥ | 1.5 |

| 7 | Peel strength with concrete after thermal aging/(N/mm) ≥ | 1.0 |

| 8 | Peel strength with concrete after UV treatment/(N/mm) ≥ | 1.0 |

| 9 | Heat resistance | No displacement, flow and slip at 80℃ for 2h |

Applied to waterproof and damp proofing engineering constructions for various underground buildings, cave depots, tunnels, subways and other municipal construction buildings etc.

HDPE polymer self-adhesive membrane (non-bitumen-based) waterproof sheet is made of various polymer

sheets as base materials covered with one self-adhesive layer and with the isolating membrane or sand layer as the isolatinglayer. Moreover, the polymer sheet includes various plastics such as HDPE, TPO, PVC, EVA, ECB, and elastomer such as EPDM.

(1) Form “skin-type” waterproof effect, eradicating water channeling.

(2) When qualified, directly assemble the reinforcement and pour the structural concrete.

(3) Convenient construction, short construction period.

(4) Excellent resistance puncture and weather, and long lifetime.

(5) Good bonding effect.

(1) Municipal works: Subway station and subway running tunnel.

(2) Highway: Highway tunnel.

(3) High-speed railway: High-speed railway running tunnel

(4) Industrial and civil building: Basement foundation slab and side wall constructed in the method of external prevention and internal pasting.